First Class Continuous Cold Rolling Mill for Copper Rod

Copper Rod Cold Rolling Production Line 1.Description Copper rod two-roller continuous cold rolling machine has the feat

Description

Basic Info.

| Model NO. | RLCR |

| Customized | Customized |

| Condition | New |

| Automatic Grade | Automatic |

| Certification | CE |

| Type | Special Casting |

| Location | Jiangsu |

| Mill Type | 2 Roller |

| Capacity | Customized |

| Motor | Siemens |

| Transport Package | Wooden Package |

| Specification | Customized |

| Trademark | Reliable |

| Origin | China |

| Production Capacity | 30 Lines/Year |

Product Description

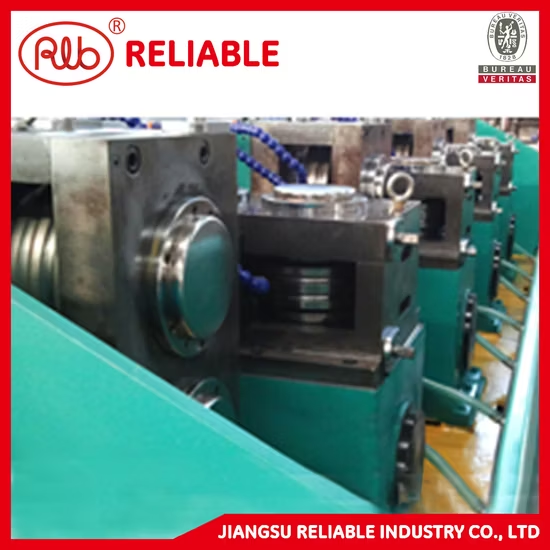

Copper Rod Cold Rolling Production Line1.Description

Copper rod two-roller continuous cold rolling machine has the features which is high efficiency, high quality, simple operation and low energy consumption.

It's made up of pay-off stand, cold rolling machine, lubrication system, cooling lubrication system, coil take-up machine and electrical control system.

It's used to roll up-casting free-oxygen copper rod by cold rolling.

Rolling mill main motor adopts DC drive; active take-up motor adopts variable frequency drive.

Digital electrical control system, PLC +human-machine interface, easy and safe for operation.

2.Technical data:

| Items | Two Rolls | Three Rolls | ||

| Inlet Rod Diameter (Mm) | Φ20 | Φ17 | Φ20 | Φ17 |

| Outlet Rod Diameter (Mm) | Φ7.8 | Φ7.8 | Φ8.0,Φ6.8 | Φ7.8 |

| Production Capacity (T/H) | ≤2.2 | ≤2.2 | 1.5-3.6 | ≤2.2 |

| Final Rolling Speed (M/Min) | Max:2.15 | 1.65 | Max:2.15 | 1.65 |

| No. Of Rolling Stand | 10 | 8 | 10 | 8 |

| Coil Weight (T) | 3-4 | 3-4 | 3-4 | 3-4 |

| Main Motor | 132KW | 110KW | 132KW 750r/min | 110KW |

| Roller Diameter (Mm) | Φ255 | Φ255 | Φ255 | Φ255 |

3.Layout:

4.Application Demonstration:

We offer Two-Roll and Three-Roll cold rolling mill

Can be used for rolling copper alloys, such as: copper magnesium alloy, copper silver alloy, copper tin alloy.

5.Video Link:

Prev: Hot Rolling Mill Production Line with Straightener and Cold Saw, Stacker, Bundling Machine

Next: Customized Carbon Steel or Alloy Steel Components for Hydraulic Cylinder

Our Contact

Send now