Lh2400 Spiral Welded Steel Pipe Making Machine Steel Tube Mill Line

Description

Basic Info.

| Model NO. | LH2400 |

| Condition | New |

| Customized | Customized |

| Application | Industry |

| Type | High Frequency Weld Pipe Mill Line |

| Quality | Good |

| Factory | Yes |

| City | Botou |

| Province | Hebei |

| Transport Package | Nude |

| Specification | LH2400 |

| Trademark | Boheng |

| Origin | Prc |

| HS Code | 8515219100 |

Packaging & Delivery

Package Size 2000.00cm * 150.00cm * 150.00cm Package Gross Weight 9000.000kgProduct Description

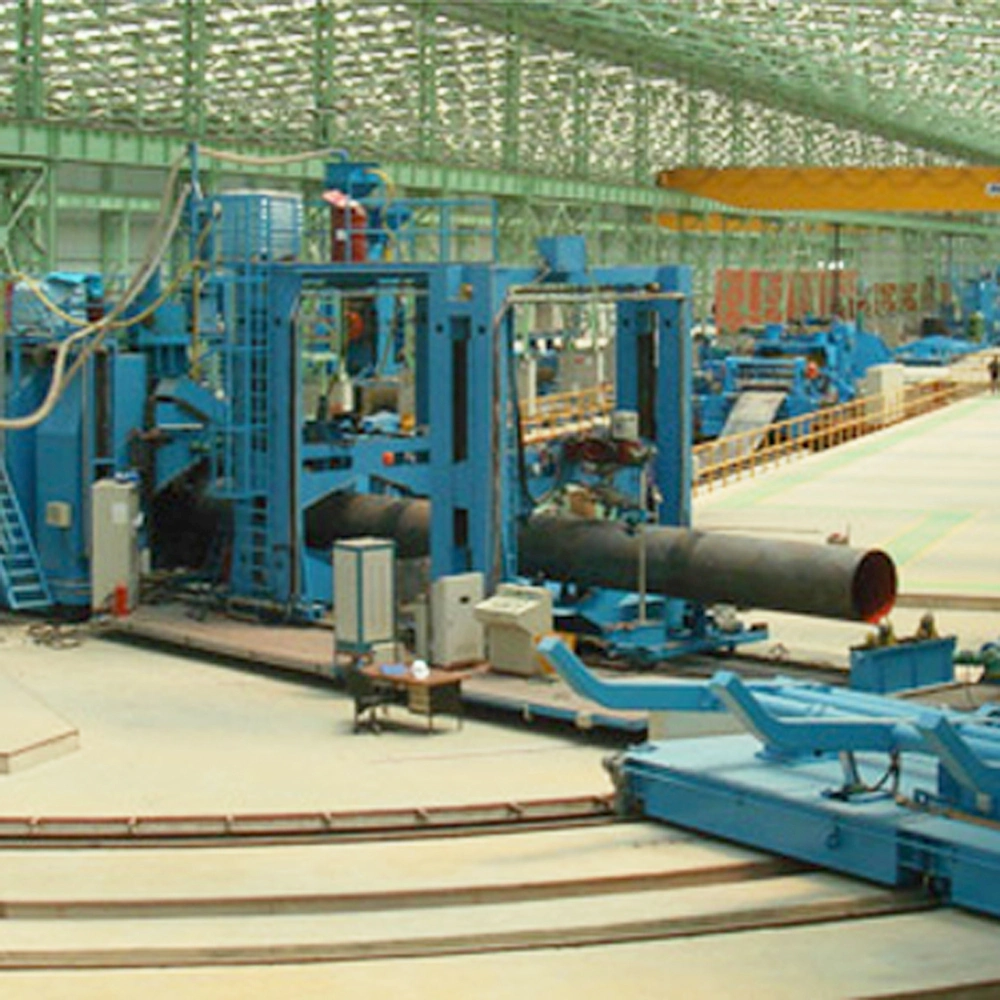

Spiral welded steel pipe making machine

Description:

Helical welded pipe unit LH-2400 is a helical welded steel pipe made of strip coil plate, extruded at constant temperature, and welded by automatic double-wire double-sided submerged arc welding process.

Main machine: Byand-2000 pipe making unit manufactured by WILSON BYAND, UK. The unit is a segmented assembly with a total weight of about 130 tons. It can be divided into four main parts for single transport, which is suitable for on-site equipment layout, on-site production and on-site steel pipe supply. The overall performance parameters of the unit are as follows:

The diameter of the steel pipe is 400×5.0mm and 3048×25.4mm

The pipe length is generally 6 ~ 30m, up to 80m

The width of the raw material plate is 700mm and 2000mm

The steel coil weighs 40 tons more

Material grade up to API 5L×65

Inside and outside timely butt welder LINCOLN DC-1500

Spiral welded pipe unit LH-2400 main drive main reducer DAVID BROWN RADICON

Spiral welding pipe unit LH-2400 equiseparation cutting machine LINCOLN PRO-CUT 125

Hydraulic system VICKERS, DENISON

Company Profile

Hebei Yongyue Electromechanical Equipment Co., Ltd. is a professional high-end cold-bending equipment manufacturer with an annual output of 100 sets of equipment, integrating independent research, production, development, sales and service.

Our company has long been committed to the development of straight seam welded pipe equipment, mold and cold bending equipment.

Our company's product quality is stable and cost-effective. Our Excellent design engineers and good processing technology ensure the quality and performance of the equipment.

Our company has been passed certifications of various systems, having a complete and scientific quality management system.

Our company's products designed not only sell well in China, but also exported to Southeast Asia, the Middle East, South America, North America, Europe and other countries and regions, won widespread praise and good reputation.

Our company all use computer software to optimize the design of cold bending equipment and engineering drawing, making drawing, installation drawing.

We have the first - class processing equipment, physical experiment equipment, non - destructive testing equipment and chemical analysis room.

We adopt the most advanced digital computer testing method to produce first-class-quality straight seam welded pipe equipment.

We own a perfect after-sales service network to provide you with fast and thoughtful service from pre-sale to after-sale.

Adhering to service principle of the quality as the root and of the credit as the base ,the general manager with all the staff welcome you to negotiate for our good cooperation.

Welcome to visit our company!

FAQ

Q: Are you manufacturer or trading company?

A: We are manufacture and trading company

Q: What about our after-sale service?

A: We provide technical support on line as well as overseas services by skillful technicians

Q: How does your factory do regarding quality control?A :There is no tolerance regarding quality control. Quality control complies with ISO 9001.every machine has to past testing running before it's packed for shipment

Q: How can I trust you that machines pasted testing running before shipping?

A: 1) We record the testing video for your reference 2) We welcome you visit us and test machine by yourself in our factory.

Q: what is the MOQ?

A: 1 setQ: Do you provide installing and debugging overseas?

A: Overseas machine install and worker training services are optional

Q: Can you make the machine according to my design or prototype?

A: Yes, we have an experienced team for working out the most suitable design and production plan for the machine that you are going to book with us.

| 1 | Q: Are you manufacturer or trading company? A: We are manufacture and trading company. |

| 2 | Q: What about our after-sale service? A: We provide technical support on line as well as overseas services by skillful technicians. |

| 3 | Q: How does your factory do regarding quality control?A :There is no tolerance regarding quality control. Quality control complies with ISO 9001.every machine has to past testing running before it's packed for shipment. |

| 4 | Q: How can I trust you that machines pasted testing running before shipping? A: 1) We record the testing video for your reference 2) We welcome you visit us and test machine by yourself in our factory. |

| 5 | Q: what is the MOQ? A: 1 set |

| 6 | Q: Do you provide installing and debugging overseas? A: Overseas machine install and worker training services are optional. |

| 7 | Q: Can you make the machine according to my design or prototype? A: Yes, we have an experienced team for working out the most suitable design and production plan for the machine that you are going to book with us. |

Prev: ERW Square Tube Mill Galvanized Pipe Making Machine Carbon Steel Pipe Machine

Next: Rbe Welded Pipe Mill, Pipe Making Machine, Tube Production Line

Our Contact