Steel Tube Mill Components for Inside Removal of Weld Bead

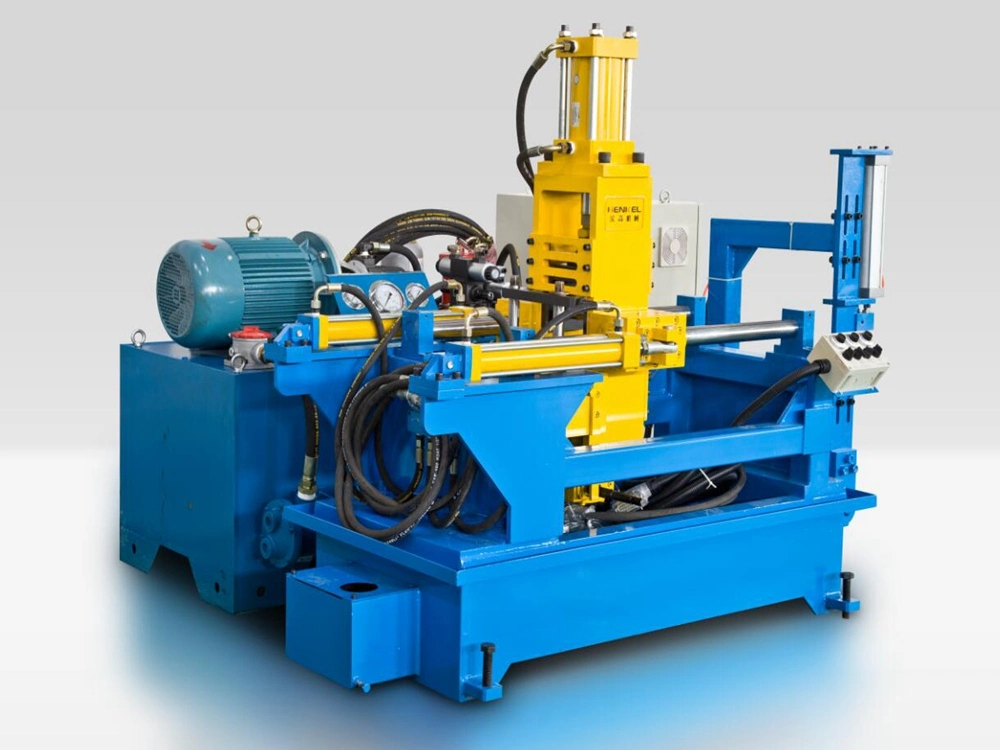

Product Details Decription •Matching: will be matched with industrial pipe making machine.•Component: inside and outside

Description

Basic Info.

| Model NO. | SZP-J-40/50/60/70 |

| Scope of Application | Industrial Tube/ Decoration Tube/ TIG Welding Tube |

| Mandrel Material | SKD11 |

| Material Applied | 300 Series,400 Series, Duplex Stainless Steel |

| Speed | 0.5-5 M/Min |

| After-Sale Service | Engineers Available to Service Machinery Overseas |

| Warranty | 1 Year |

| Effect | Removing Weld Bead, Make Internal Tube Wall Smooth |

| Roller Material | Cr12MOV |

| Cooling Type | Air Cooling |

| Type | on-Line |

| O.D. Range | 12-114 mm |

| Condition | New |

| Transport Package | Water Proof Film and Pallets |

| Trademark | SEKO |

| Origin | China |

| HS Code | 8479819000 |

| Production Capacity | 500 Sets Per Year |

Product Description

Product Details

| Type | Welding type | O.D.(mm) | Thickness (mm) | Speed (m/min) | Motor Power (KW) | Capacity of Oil Cylinder | Size(L*W*H)(m) |

| SZP-J-40 | TIG | 12-38 | 0.4-2.0 | 1-5 | 7.5 | 200L | |

| SZP-J-50 | TIG | 25-76 | 0.5-2.5 | 1-5 | 7.5 | 300L | |

| SZP-J-60 | TIG | 50.8-114 | 0.5-3.0 | 0.5-4 | 11 | 300L | |

| SZP-J-70 | TIG | 89-168 | 1.0-4.0 | 0.5-3.5 | 18.5 | 300L | |

| SZP-J-80 | TIG | 300L | |||||

| SZP-J-90 | TIG | 89-219 | 1.0-5.0 | 0.5-3.5 | 18.5 | 300L |

Decription

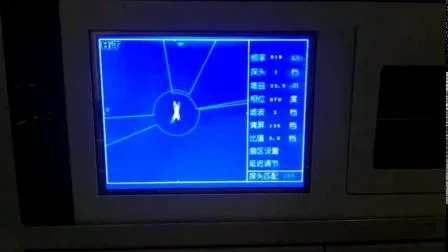

•Matching: will be matched with industrial pipe making machine.•Component: inside and outside weld seam leveling equipment, hydraulic air control system, automatic electric hydraulic air control system with PLC, hydraulic cycling equipment for mold and roll.•Feature: stainless steel welded pipe welding leveling device and a built-in SKD11 mandrel and utilization of stainless steel welded pipe rolling device automatic reciprocating roller, through the control to achieve the strength and make stainless welded pipe and weld leveling, completely remove the internal and external welding and with more respect to seamless requirement.•Working procedure: with more than the high and weld stainless welded pipe after level after rolling roll over, high removed, welded pipe section into a level in welding rods, elliptical stuck pipe welded pipe, followed by vertical roll rolling, welded pipe section into a mandrel, with full welded pipe separation in the frame of the cylinder back to when proper place, then the second rolling cycle.

Application

After the internal weld is leveled by stainless steel tube mill components for inside removal of weld bead , the stainless steel welded pipe has smooth inner and outer walls. After polishing to a certain extent, it can be used for high-end industrial applications such as sanitary fluid pipes, water pipes, heat exchange pipes, oil and gas pipelines, etc., and can also be widely used in food. Industry, petroleum industry, pharmaceutical and chemical industry, sanitary ware industry, etc.Some people may have questions: whether the welded pipe can be polished directly without internal flattening. The answer is: no! Without the inner flattened welded pipe, or the flattening effect is poor, the number of internal and external polishing will be increased, which directly affects the thickness of the finished pipe, so that the pipe wall tolerance becomes larger and the weight is reduced. Indirectly increases production costs and harms the interests of manufacturers.

About SEKO

Guangdong Shunde Seko Machinery Co., Ltd. founded in 2009. We are an industrial stainless steel welded pipe making machine manufacturer, with 20 year experience, which integrates design, research and development, manufacture, sale, after-sale service and other supporting service. By virtue of its excellent credit, high performance products and considerate service, our company has won a large group of loyal customers and is recognized by its peers and the authoritative organizations highly. Its products are exported to Dubai, Russia, India, Thailand, Pakistan, Vietnam and ect..

Our Partner

FAQ

1. Which countries your products are exported to?Our products are sold all over the world and with related certifications.2.How about the warranty?All our products have one year quality warranty, during the warranty time, the spare parts replacement is free. And we provide life long time technical support and other assistance.3.How to install your machine?Usually speaking, engineers will be sent to your factory to help to install and adjust the machines. We also have paper installation instructions and videos, teaching you till you command it.4. Which export port you use?Any China ports. Commonly, we will use Shenzhen port. But it can be appointed as you like.5. How about the payment terms and delivery time ?Payment terms for small machines: 100% T/T/ Western Union/Cash in advance.The big machines and big amount: 40% deposit, 60% before shipment (we will shoot total delivering process for customer's confirmation) and the related papers. You can pay by T/T,L/C, Western Union or other ways.The machine delivery time is within 45-90 days.6.Is your goods with ISO9001 or CE certificate ?Yes, all our goods has ISO certificate. All machines are high quality goods.

7.What is your nature of your company:dealer or factory ?We are manufacturer with a big factory ,warmly welcome to visit our factory and contact us.

Contact us

Prev: Tube Mill Components for Electromagnetic Control System

Next: Tube Mill Components for Laser Welding Seam Tracking System

Our Contact

Send now